|

|

INSTALLATION AND USAGE GUIDELINES |

|

|

|

|

USE AND CARE |

|

|

|

|

|

|

|

|

|

|

|

Maintenance |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Examine the gage glass regularly for any signs of clouding, scratching, |

|

erosion, or corrosion. In new processes, the glass should be inspected |

|

daily until the need for replacement becomes apparent. This will help |

|

establish the routine inspection and routine replacement cycles. |

|

|

|

|

|

|

|

|

|

|

Cleaning |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Keep gage glass clean using non-abrasive commercial glass cleaners. |

|

Where regular gleaners do not seem to work, use dilute acides shuch as |

|

Hydrochloric (muriatic) acid. Always observe safety rules when handing |

|

handling hazardous cleaning solutions. Never use wire brushes, metal |

|

scrapers, or harsh abrasives which could scratch the glass. |

|

|

|

|

|

|

|

|

|

|

Inspection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Scratches, corrosion, chips, surface flaws, or nicks on the surface or |

|

edges weaken the gage glass. To examine for these, shine a very |

|

bright concentrated light ("Burton Lite" or powerful flashlight) at about |

|

45 degree angle. Anything which glistens and catches the fingernail |

|

or any star-shaped or crescent-shaped mark which glistens, is |

|

|

cause for replacement. Any gage glass which appears cloudy or |

|

|

roughened and will not respond to cleaning procedures, should be |

|

|

replaced. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Storing |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Keep gage glasses in original packaging until ready to install. |

|

|

|

|

|

|

|

|

|

|

Handling |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Avoid bumping, chipping, or scratching gage glass. Any glass-to-glass |

|

contact can cause scratches and must be avoided. |

|

|

|

|

|

|

|

|

|

|

|

Installation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

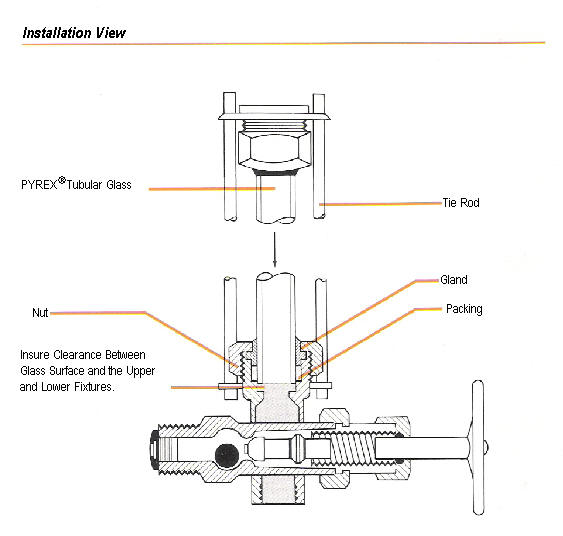

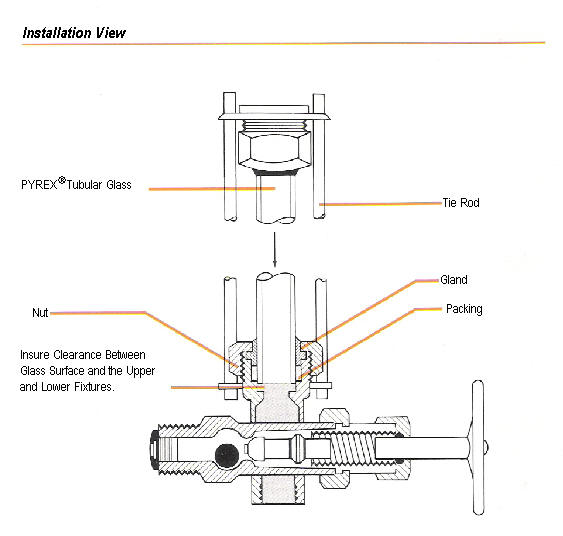

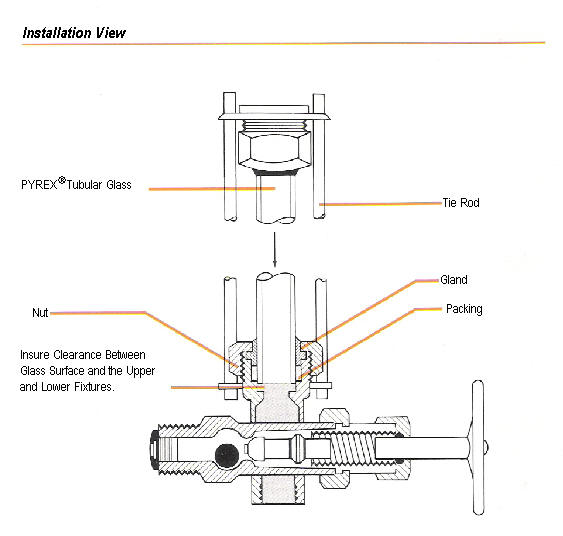

Always follow tubular gage manufacturer's recommended procedures for |

|

glass replacement. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Before installing a gage glass, remove all deposits from the seal contact |

|

surfaces of the gland nut and the gland (where used). Check sealing |

|

surfaces for cleanliness and smoothness. Once the gage glass has been |

|

removed from its mounting, regardless of the reason for its removal, |

|

discard the glass and replace with a new piece. |

|

|

|

|

|

|

|

|

|

|

|

Always use new paking, seals, and/or O-rings (if required) when |

|

|

replaceing a tubular gage glass. Used packing, seals, and O-rings will |

|

not properly support the gage glass or provide the proper pressure |

|

|

seal without stressing the glass. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1. Hold fittings rigidly to prevent misalignment, which can cause severe |

|

bending stresses in the glass, when packing nuts are tightened. |

|

|

|

|

|

|

|

|

|

|

2. Provide metal washers so nuts can be tightened without twisting |

|

packing or tube. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3. Provide positive, but not excessive, clearance between glass, packing |

|

nuts, and bearing washers. |

|

|

|

|

|

|

|

|

|

|

|

|

|

4. Keep glass short enough to allow for expansion. |

|

|

|

|

|

|

|

|

|

|

|

5. Provide positive clearance between the ends of the gage glass and |

|

the metal fittings. Glass-to -metal contact will keep the gage galss from |

|

expanding and cause breakage. |

|

|

|

|

|

|

|

|

|

|

|

|

|

6. Tighten packing nuts enough to prevent leakage, but not so much |

|

that you hinder expansion and contraction. Follow gage manufacturer's |

|

recommendations. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7. Generally, you can use cylindrical or conical runner packings for LOW |

|

and MEDIUM pressures. HIGHER pressure and HIGH temperature |

|

may require specialized packings. In all cases you should follow the |

|

recommendations of the gage manufacturer. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sources: Corning Incorporated brochure "Tubular Gage Glasses" |

|

|

Copyright 1991. |

|

|

|

|

|